1. Introduction:

Industries operating in highly corrosive environments—such as chemical processing, marine engineering, and pharmaceuticals—often face significant challenges using standard stainless steels like 304 or 316. These materials can degrade over time when exposed to chlorides, strong acids, or high temperatures, leading to frequent maintenance, system downtime, and increased costs. This has led engineers and procurement teams to search for a more resilient solution.

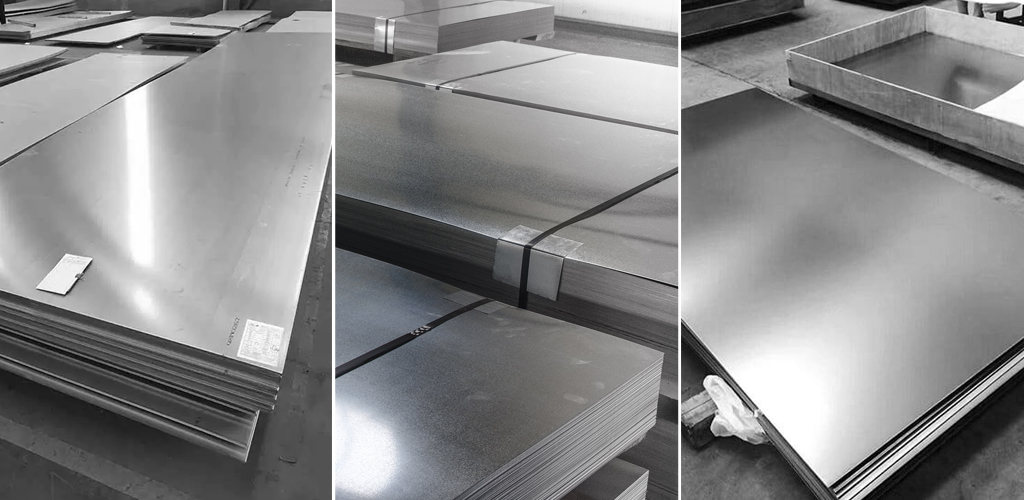

2. Product Introduction:

Stainless Steel 317L Sheets are a low-carbon, molybdenum-bearing austenitic stainless steel product designed to offer exceptional resistance to chemical attack. Manufactured according to international standards such as ASTM A240 and ASME SA240, these sheets are engineered for enhanced performance in aggressive industrial environments.

As trusted Stainless Steel 317L Sheets Suppliers in India and Stainless Steel 317L Sheets Stockists in India, many firms now stock a wide range of thicknesses and finishes tailored for specialized applications.

3. Advantages of Stainless Steel 317L Sheets

Superior Corrosion Resistance

The molybdenum content (3-4%) offers better resistance to pitting and crevice corrosion, especially in chloride-rich and acidic environments.

Excellent Weldability

Due to its low carbon content (the “L” in 317L), the sheets minimize the risk of carbide precipitation during welding, maintaining corrosion resistance in welded zones.

High-Temperature Stability

SS 317L can perform reliably at elevated temperatures, making it ideal for heat exchangers and pressure vessels.

Durability and Strength

These sheets offer great tensile strength and toughness, ensuring longevity and structural integrity even under mechanical stress.

Conformance to Global Standards

Products adhere to ASTM A240 / ASME SA240 specifications, ensuring uniformity and performance across applications.

4. Real-Life Uses of SS 317L Sheets

Chemical Processing Equipment

Used in reactors, evaporators, and heat exchangers that handle aggressive chemicals.

Marine and Offshore Platforms

Ideal for components exposed to saltwater and seawater spray.

Pharmaceutical Plants

Used in sterile processing environments and cleanroom walls.

Pulp & Paper Industry

Applied in bleach washers and digester components where chloride exposure is high.

Petrochemical and Refinery Units

Employed in storage tanks, piping systems, and pressure vessels.

5. How Stainless Steel 317L Sheets Solve Industrial Problems

By offering superior resistance to corrosion and thermal stress, Stainless Steel 317L Sheets significantly reduce the risk of material failure and costly replacements. The low carbon content ensures that the sheets maintain corrosion resistance even after welding—solving one of the key limitations of conventional stainless steels.

The outcome?

-

Lower maintenance costs

-

Extended equipment life

-

Improved operational safety

-

Enhanced ROI for industrial systems

As leading Stainless Steel 317L Sheets Suppliers in India and Stainless Steel 317L Sheets Stockists in India continue to expand inventories, access to this high-performance material has become more streamlined and cost-effective.

6. Conclusion

Stainless Steel 317L Sheets are the material of choice for industries seeking long-term reliability, superior corrosion resistance, and high-temperature stability. Backed by ASTM A240 / ASME SA240 standards and widely available through top Stainless Steel 317L Sheets Stockists in India, these sheets are redefining durability in challenging environments.